Back in 2016, Elon Musk posted a tweet in which he announced bringing an end to the worldwide traffic chaos. His enterprise "The Boring Company" launched a competition in summer 2020: The aim is to reinvent tunnel boring machines - making them faster and more efficient. The team at DHBW Mosbach impressed with its innovative concept - and consequently the valves made by müller co-ax gmbh installed in it.

Tunnelling is an attractive alternative to above-ground road traffic. By expanding the road network and reducing land usage above ground, the aim is to reduce and rectify the high volume of traffic on the roads.

The "not a boring competition" sponsored by Musk is intended to promote innovations in tunnel construction and to make these faster, cheaper and more flexible.

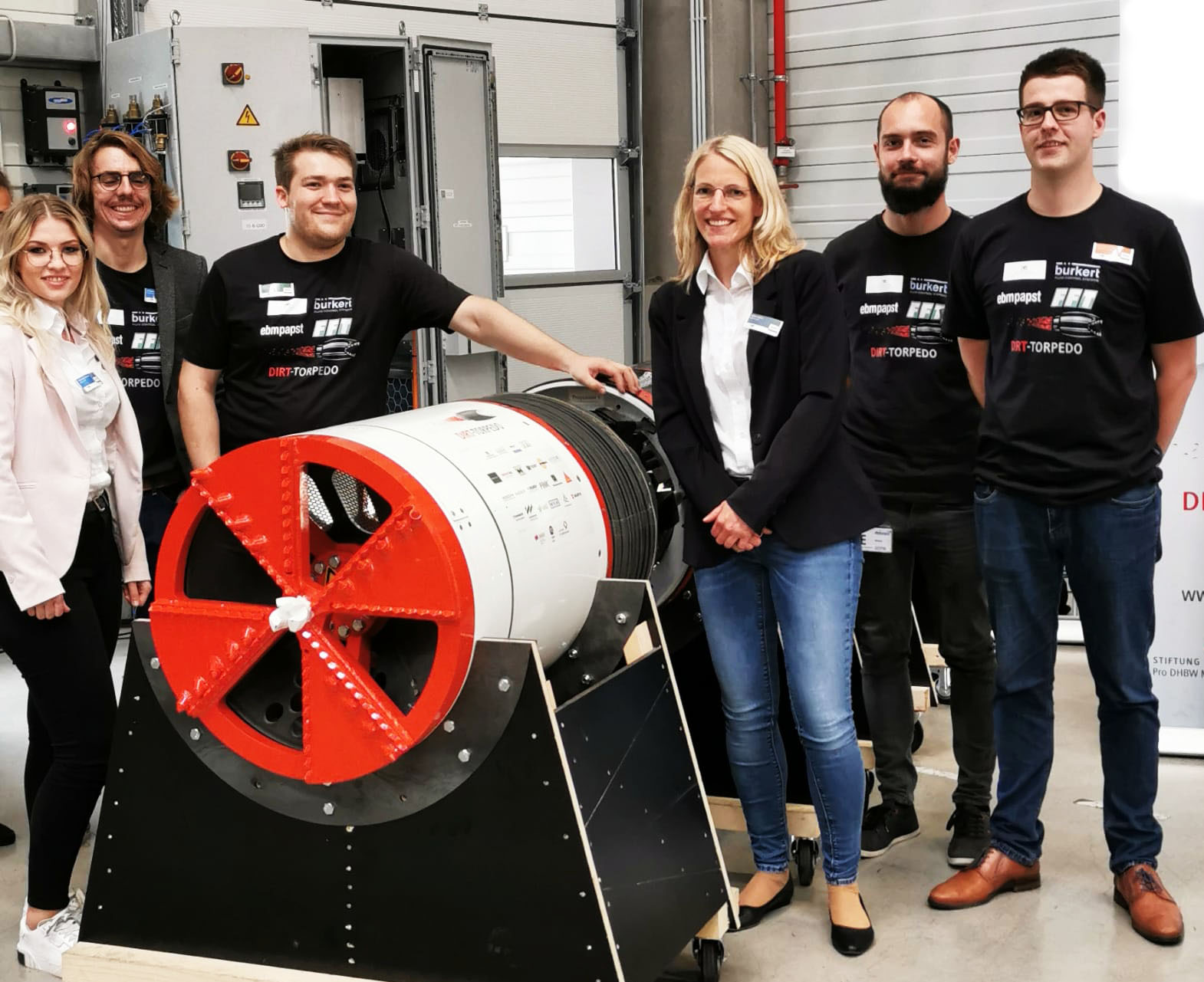

Only twelve of the 400 international teams that applied were able to impress the jury with their technical design. The finalists include the "Dirt Torpedo" team from DHBW in Mosbach with their innovative concept. The intention here is not to build the tunnel as usual using pipe jacking, but instead to line the tunnel walls during the boring process.

Team leader Adrian Fleck summarises the composition of the tunnel boring machine: "At the front is a boring unit, which removes, crushes and takes away the earth material. Behind it is a propulsion unit, which enables translational and rotational movements of the tunnel boring machine and hence can contract and expand like a worm. The innovation is the last part: the machine uses this to build a tunnel itself out of mortar."

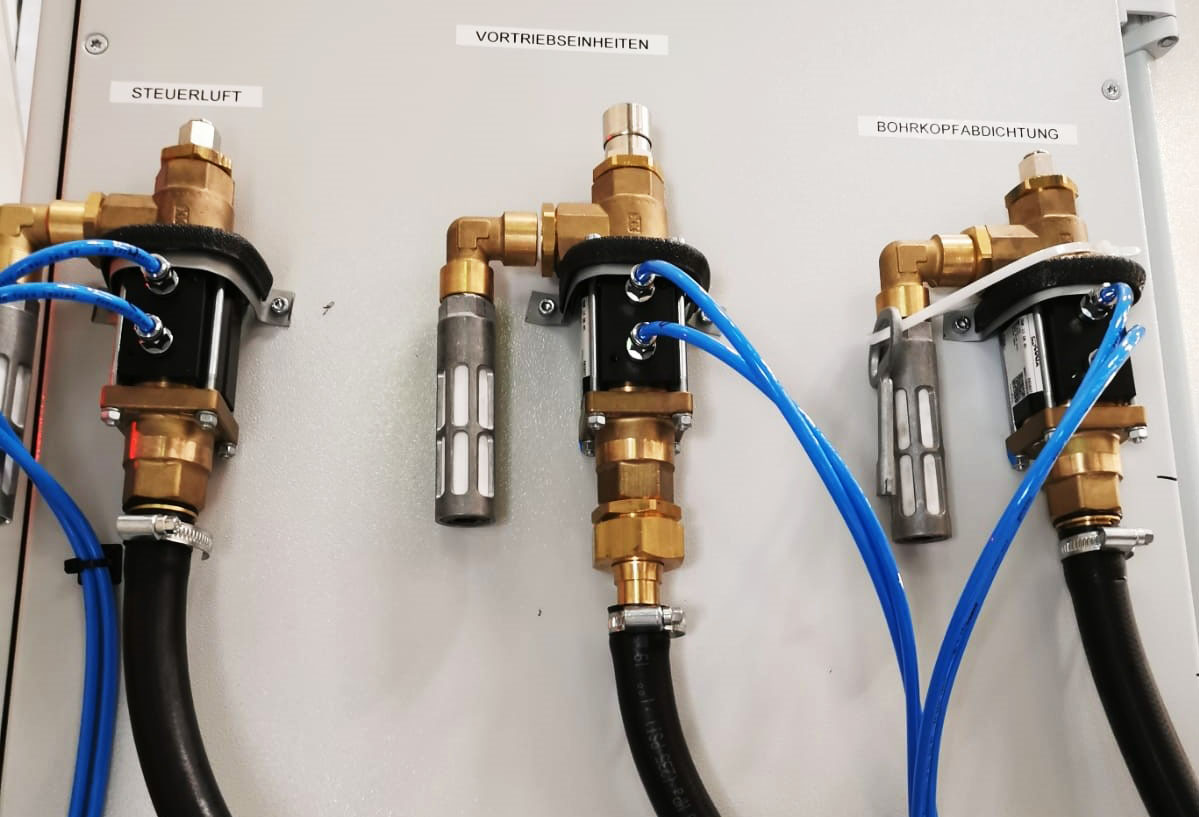

The team from DHBW Mosbach opted at a very early development stage for valves from coax, which are used as main valves for the supply lines in the tunnel boring machine. One of the supply lines delivers compressed air to the air cushions on the propulsion unit. "We were on the lookout for reliable valves that meet the requirements 100 %. Especially when dealing with large currents, the externally controlled coax valves are ideally suitable. Due to the coaxial design, these provide a high flow, even with a small valve diameter," says Fleck.

Besides this project, coax valves are used in tunnel construction in a wide variety of areas: also in the area of the boring unit, coaxial valves are used on the water jets for cleaning purposes. In places where there is no compressed air, electrically operated coaxial valves can help in various pressure levels.

To control the medium of water glass, a powdered glass mixed with chemicals, which is dissolved in water and which acts as a catalyst in concrete, cartridge valves made by coax are predominantly used. Also when working with bentonite, which is used as a lubricant to reduce the friction between the soil and the outer pipe. By integrating pipe seals, cartridge valves are particularly well suited for abrasive and viscous media and, due to their design, can be maintained in just a few minutes if needed by changing the valve cartridge. The coax product portfolio has even more to offer for the tunnelling sector: the all-rounder, the coaxial valves, by making flexible adjustments such as the integration of flush bores, can also be used for applications in tunnel construction.

müller co-ax gmbh

Katja Krämer

Marketing & Communication