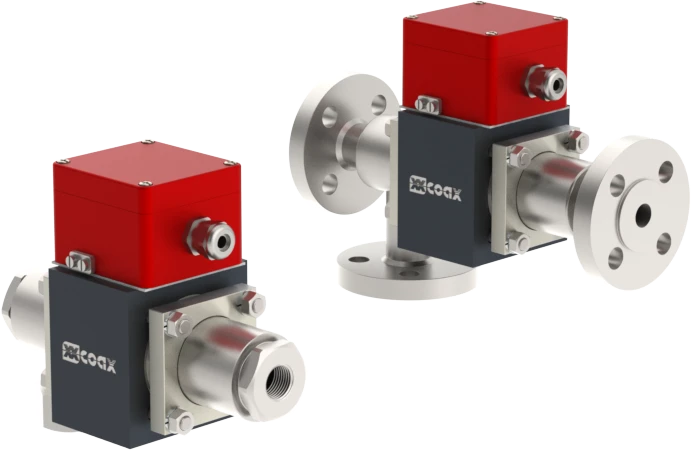

müller co-ax gmbh presents the next generation of explosion-proof solenoid valves with the new Ex-Valve-Series-D. Designed for safe use in gas and dust explosion hazard zones, the Ex-Series-D meets the latest requirements of ATEX Directive 2014/34/EU and the IECEx standards. With standardized voltage variants, increased temperature resistance, and optimized heat dissipation, the new series sets new benchmarks in safety and efficiency.

The new design features double protection as well as a newly developed valve housing for improved heat dissipation. This means that the Ex-Valve-Series-D not only complies with current legal requirements, but also offers operators and plant manufacturers long-term investment security.

“With the Ex-Series-D, we are improving safety and flexibility in potentially explosive atmospheres to a new level.” “The standardized voltage options, optimized temperature management, and extended certifications significantly simplify planning and commissioning for our customers,” explains Martin Bogert, Head of Quality Management at müller co-ax gmbh.

Unique about the Ex-Series-D are the eleven uniform voltage variants from 20 V to 230 V for all nominal sizes of valves K10, K15, K20, K32, K40, and K50. This allows a wide variety of control concepts to be implemented worldwide without requiring any adaptations. The new temperature class T3 allows operating temperatures from -30 °C to +120 °C.

A unique feature is that all Ex-Series-D valves are pressure-balanced, compact, and suitable for both gas and dust explosion hazard zones. Thanks to modular mounting, the valve spacing can be reduced from 100 mm to just 30 mm, thus saving space, assembly time, and installation costs. Optionally, universal power connectors with an integrated rectifier board or DC-only versions are available.

The Ex-Series-D is ATEX- and IECEx-certified. This means that the valves are ready for international use and meet all current explosion protection requirements.

The Ex-Valve-Series-D has been specially developed for demanding applications in the chemical and petrochemical industries, the oil and gas industry, the energy and process industries, as well as in mechanical and plant engineering. Due to its reliability and safety in hazardous areas, it is also used in the pharmaceutical and food industries. Thanks to the extended temperature range and robust design, the Ex-Series-D is suitable for both low ambient temperatures from -30 °C to +40 °C/ +80 °C (T4) and hot media up to +120 °C (T3).

With the Ex-Valve-Series-D, müller co-ax gmbh offers a completely revised and future-proof product range for explosion-proof applications. Compact, powerful, and compliant with global standards, the Ex-Series-D stands for maximum safety, efficiency, and flexibility in process control.

müller co-ax gmbh is a leading international valve manufacturer. Since its founding in 1960, the company, which now has over 300 employees, has specialized in the development and production of coaxial valves. Innovative solutions for a wide range of media and applications are developed at the company headquarters in Forchtenberg. coax technology sets standards in demanding applications in the mechanical engineering, marine, chemical, energy, oil and gas, aerospace, and construction industries.

müller co-ax gmbh

Katja Krämer

Marketing & PR