Hydrogen offers an important alternative to fossil fuels on the road towards greenhouse gas neutrality. Two process steps are of key significance here: the production and storage of hydrogen. Power-to-X refers to the storage and use of excess electricity that is generated from renewable energy sources. Amongst other things, this includes the production of green hydrogen which arises through the conversion of renewable electricity.

The applications for hydrogen are highly diverse. In addition to direct use, hydrogen can be used in industry for the production of ammonia or methanol, or used in steelworks or refineries. As well as industrial applications, green hydrogen plays a major role in particular in the decarbonization of the energy sector and in mobility. Sector coupling is therefore considered a key concept for the energy revolution.

müller co-ax gmbh offers solutions for various technologies along the entire H2 value creation chain:

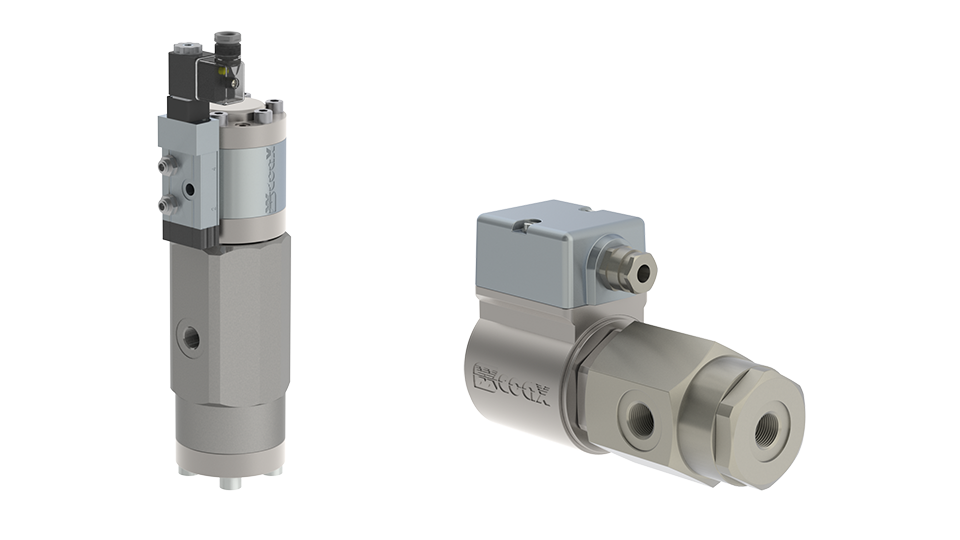

coax valves stand out for their hydrogen-resistant materials and very compact size, while providing a large flow rate and a broad pressure range. This makes them especially suitable for installation in very confined spaces, such as in containers for PEM electrolysis systems. The “Open/Closed” valve position can be accessed directly from the limit switch display.

coax valves and important requirements of TRGS 500 (technical rule for hazardous materials):

Especially the magnetic coax valves are designed to stay “tight to the atmosphere”, even when the seals are worn. There is no operationally open connection to the atmosphere, the valve type is closed, and tightness to the outside is ensured. Escape of hazardous materials is securely prevented, so direct skin contact with the medium won’t happen. These valve fittings are best for use with explosive or poisonous media, whether for gaseous hydrogen (up to 100%) or liquid ammonia or methanol.

Hydrogen is a cornerstone of the chemical industry and in the quest for greenhouse gas neutrality, it is one of the most important alternatives to fossil fuels.

For the long term, the industry is relying on electrolysis-based hydrogen production, where water is broken down using electric current from renewable energy sources. This results in green hydrogen, which is free of CO2 and therefore climate neutral.

There are also different approaches to hydrogen storage and refilling, due to challenges in handling hydrogen, and the specific properties must be considered. Compared to many hydrocarbons, hydrogen has low volumetric energy density, so for storage, the hydrogen must be very strongly compressed or liquefied.

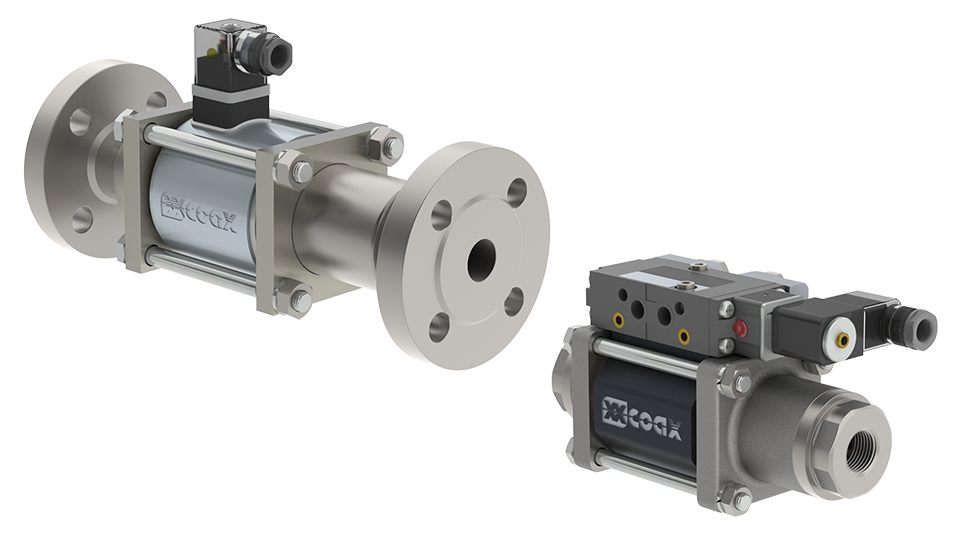

The lateral high-pressure valves, in which the valve drive is positioned on the side, are used wherever high pressures of up to 500 bar at a high flow rate are controlled. The high-pressure valves are available either with a magnetic or pneumatic drive. Amongst other applications, the valves are used in refueling processes or in high-pressure test rigs.

The coaxial high-pressure valves are specially designed for high-pressure applications of up to 400 bar. They impress due to their compact design. In addition to the high-pressure range, cryogenic media down to -196°C can also be controlled with the KB series. Coaxial high-pressure valves are used in hydrogen refueling or fuel cell drives, amongst other things.

The coaxial valves are used in applications of up to a maximum of 100 bar. Direct acting and externally controlled valves are available to our customers. Different designs in terms of materials, seals, connections, and other options make the coax valves supremely flexible. The customer obtains a valve which is perfectly customized to the requirements. Among other applications, coaxial valves are used in the production of hydrogen by means of electrolysis or pressure swing adsorption as well as test rigs or in industry.